-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Considering a rear bumper doubled as an air tank.

Discussion in '2nd Gen. Tacomas (2005-2015)' started by toyoda, May 24, 2011.

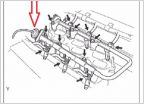

2006 fuel pressure check

2006 fuel pressure check '05 Taco Cabin Air Filter

'05 Taco Cabin Air Filter Spiral cable or not?

Spiral cable or not? Another vibration thread...NO LIFT

Another vibration thread...NO LIFT Auto Transmission Fluid Level

Auto Transmission Fluid Level