-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Hub Bolt Replacement - How to?

Discussion in '2nd Gen. Tacomas (2005-2015)' started by 13TRDBaja, Jul 20, 2014.

Will my 9'4" Longboard fit in a short bed Taco?

Will my 9'4" Longboard fit in a short bed Taco? Intro and…hot foot

Intro and…hot foot Sunglass Clips for Fat A** Sun Visors???

Sunglass Clips for Fat A** Sun Visors??? In Cabin Filter

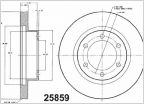

In Cabin Filter Brakes

Brakes TPMS

TPMS