-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Quick Links: Connecting a portable air compressor to dual battery system

Connecting a portable air compressor to dual battery system  Adding horns, can I install a beefier stock relay?

Adding horns, can I install a beefier stock relay?  Anyone run one of the KIWI scanners

Anyone run one of the KIWI scanners  How do I know if I need a relay?

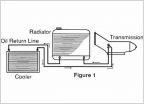

How do I know if I need a relay?  TRANSMISSION . Transmission coolers for all Toyotas ... Write up with many pictures

TRANSMISSION . Transmission coolers for all Toyotas ... Write up with many pictures  Torque Wrenches In-LB and Ft-LB

Torque Wrenches In-LB and Ft-LB

Welding information anyone?

Discussion in 'Technical Chat' started by TGurau, Aug 18, 2011.