-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

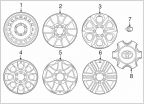

Lug nut fitment

Discussion in 'Wheels & Tires' started by Thundjet, Apr 2, 2012.

Anyone done this?!?!

Anyone done this?!?! Smaller tire fitment

Smaller tire fitment Fitting 315/70 17s on my taco

Fitting 315/70 17s on my taco FJ Trail Team Rims

FJ Trail Team Rims Wheel sensor question?

Wheel sensor question? Lug nuts for spare steel wheel

Lug nuts for spare steel wheel