-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

For Those Who Know How to Solder...

Discussion in 'Audio & Video' started by dysfunctnlretard, Oct 17, 2009.

New install of woofers and it sounds terrible.....help

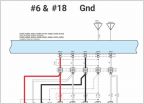

New install of woofers and it sounds terrible.....help The elusive jbl amp wiring diagram

The elusive jbl amp wiring diagram Pac SWI-JACK Wiring Help Needed

Pac SWI-JACK Wiring Help Needed SWI-JACK questions

SWI-JACK questions How to: DIY OEM mic retention 2014 Carplay & Android Auto

How to: DIY OEM mic retention 2014 Carplay & Android Auto