-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Ahh damn, my rear axle seals are leaking?

Discussion in '1st Gen. Tacomas (1995-2004)' started by btu44, Sep 7, 2018.

Page 1 of 3

Page 1 of 3

Anyone know the part #

Anyone know the part # I'm confused (among other things)

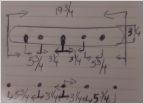

I'm confused (among other things) 2004 tacoma Nerf Bars replacement step pads

2004 tacoma Nerf Bars replacement step pads New wheel bearing and hub installed...finally

New wheel bearing and hub installed...finally