-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Whiteline Bushings, TC Alignment Tabs, SPC UCA's and Home Alignment

Discussion in '2nd Gen. Tacomas (2005-2015)' started by gunn_runner, Nov 12, 2018.

Need help with a front axle seal part #

Need help with a front axle seal part # Awful belt squealing sound 30mph+ and failing u-joint

Awful belt squealing sound 30mph+ and failing u-joint Adding Nav/Sat. Radio

Adding Nav/Sat. Radio Hmmm, Stereo and/or Driving light upgrade?

Hmmm, Stereo and/or Driving light upgrade? Identify this part

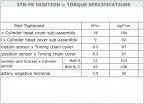

Identify this part 2009 4-Cylinder Tacoma Spark Plug Torque Specs

2009 4-Cylinder Tacoma Spark Plug Torque Specs