-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

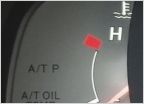

ANOTHER, but important 4WD ADD ACT TIMING talk and positions...

Discussion in '1st Gen. Tacomas (1995-2004)' started by DC92T, Dec 2, 2018.

1st gen ABS delete

1st gen ABS delete How to go about replacing transfer case motor?

How to go about replacing transfer case motor? 1st gen ball joints part numbers

1st gen ball joints part numbers Dash and Shifter bulb replacement

Dash and Shifter bulb replacement Moog LCA Bushing Failure

Moog LCA Bushing Failure