-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

2.7l Cylinder 3 misfire

Discussion in '1st Gen. Tacomas (1995-2004)' started by Lukegoes14, Jun 1, 2023.

Page 4 of 4

Page 4 of 4

Squirrel Wrecked My Baby. Seeking Wire Harness Knowledge and Help.

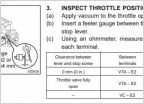

Squirrel Wrecked My Baby. Seeking Wire Harness Knowledge and Help. Throttle body

Throttle body What floor jack height is needed

What floor jack height is needed Need to refill nitrogen in my king shocks

Need to refill nitrogen in my king shocks