-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Transmission R-A60 manual transmission information . Your 6 speed transmissiom (WRITE UP )

Discussion in 'Technical Chat' started by gearcruncher, Aug 2, 2014.

Page 5 of 10

Page 5 of 10

2gen oil filters

2gen oil filters Winch Wiring Advice Needed

Winch Wiring Advice Needed Correct Exedy Clutch for 05 V6 4x4

Correct Exedy Clutch for 05 V6 4x4 What type of spark plug should I buy for a 2TR-FE engine?

What type of spark plug should I buy for a 2TR-FE engine? Adding Backup Camera Display

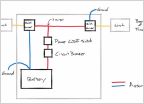

Adding Backup Camera Display Fridge, solar, battery help!!!

Fridge, solar, battery help!!!