-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Bolts welded on?

Discussion in 'Technical Chat' started by Stryker20000, Dec 11, 2018.

Pop and Lock for 2019 Access Cab

Pop and Lock for 2019 Access Cab Which portable power station for my new fridge?

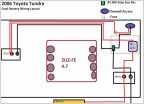

Which portable power station for my new fridge? Can you Connect a BS ML-ACR to a Bus Bar? Wiring Layout Help Needed.

Can you Connect a BS ML-ACR to a Bus Bar? Wiring Layout Help Needed. 2nd gen lower steering shaft rebuild DIY :)

2nd gen lower steering shaft rebuild DIY :) Question about keys

Question about keys