-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Install light bar - epoxy??

Discussion in 'Lighting' started by ZrowGz, Jan 13, 2019.

Led bar 126w harness?

Led bar 126w harness? Interior LED bulb package

Interior LED bulb package Fog Light Harness

Fog Light Harness Reverse light upgrade

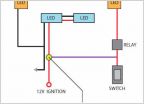

Reverse light upgrade Lightbar relay switch help

Lightbar relay switch help How to make 12V on actually turn lights off

How to make 12V on actually turn lights off