-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

4.0L V6 with bad head gasket (repair or replace?)

Discussion in '2nd Gen. Tacomas (2005-2015)' started by zguy1, Oct 16, 2022.

Page 6 of 8

Page 6 of 8

Where to find this pigtail for turn signal mirror?

Where to find this pigtail for turn signal mirror? 2011 tacoma steering wheel shaking in high speeds with spacers normal? Or not?

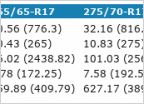

2011 tacoma steering wheel shaking in high speeds with spacers normal? Or not? Tire question

Tire question A/C - post your alternative cooling setups

A/C - post your alternative cooling setups