-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

The Impossible Bolt

Discussion in 'Technical Chat' started by Mach375, Apr 19, 2025.

Non intermittent wipers

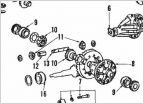

Non intermittent wipers Bearing Part Number

Bearing Part Number Thoughts on this fuse box? No busses?

Thoughts on this fuse box? No busses? No radio....need new antenna/ cable

No radio....need new antenna/ cable DIY - Build and install a Bussmann RTMR Fuse/Relay Block

DIY - Build and install a Bussmann RTMR Fuse/Relay Block