-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

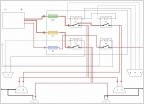

Fixing A P0500 Check Engine Light By Re-Soldering The Instrument Cluster

Discussion in '2nd Gen. Tacomas (2005-2015)' started by Orange Dave, May 23, 2025.

Squeaking AC with AC off?

Squeaking AC with AC off? Stock toyota oil filter or any brand oil filter?

Stock toyota oil filter or any brand oil filter? Snorkel

Snorkel N-Fab Nerf Steps

N-Fab Nerf Steps Custom Headlight Harness Build

Custom Headlight Harness Build