-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

DJM 2nd Gen C-Notch Tips

Discussion in 'Street Trucks' started by rat107, Apr 15, 2015.

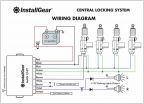

Electric door locks and windows 2009 regular cab

Electric door locks and windows 2009 regular cab Low pro bump stops front

Low pro bump stops front Bilstein 4600 Fronts part numbers

Bilstein 4600 Fronts part numbers Lug conversion

Lug conversion Installed 3" blocks and the ride is a bit harsh for me.

Installed 3" blocks and the ride is a bit harsh for me. Will these bilsteins work for lowering?

Will these bilsteins work for lowering?