-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Gas Gauge Issue

Discussion in 'Technical Chat' started by Johnny Monsoon, Feb 15, 2009.

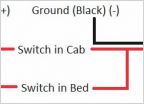

Question: Double Switch DIY Lighting

Question: Double Switch DIY Lighting Pre-Wiring Switches using Carling VCH Switch Housings

Pre-Wiring Switches using Carling VCH Switch Housings Viair 88p Hardwired

Viair 88p Hardwired Constant power usb port

Constant power usb port Mesh cover. short box

Mesh cover. short box Non intermittent wipers

Non intermittent wipers