-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Help! Soldering aluminum wires

Discussion in '1st Gen. Tacomas (1995-2004)' started by Caligula, Jul 22, 2015.

Replacing the fuel filter

Replacing the fuel filter 2001 trd elocker rear axle shafts

2001 trd elocker rear axle shafts A-pillar Scangauge III Mount

A-pillar Scangauge III Mount Leaking Transmission Pump Seal = Replace Transmission??

Leaking Transmission Pump Seal = Replace Transmission?? Sealed Beam Replacement headlights... what the hell did I buy? Help

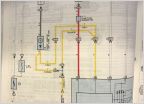

Sealed Beam Replacement headlights... what the hell did I buy? Help Alternator Draining Battery

Alternator Draining Battery