-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

How-to: Rebooting a Tacoma CV Axle

Discussion in '1st Gen. Tacomas (1995-2004)' started by turbodb, Apr 15, 2019.

Page 1 of 2

Page 1 of 2

Does anyone make a Sway Bar Extended Link?

Does anyone make a Sway Bar Extended Link? Which brake rotors should I get?

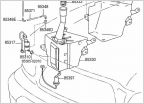

Which brake rotors should I get? WTH-The Washer Fluid Bottle?

WTH-The Washer Fluid Bottle? I need help picking out new Head Light Bulbs

I need help picking out new Head Light Bulbs 2001 Tacoma. Driver's side key won't insert into the lock.

2001 Tacoma. Driver's side key won't insert into the lock. Questions about swapping old sealed beams for hella e-codes….

Questions about swapping old sealed beams for hella e-codes….