-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

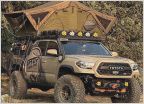

Light weight slider options

Discussion in '3rd Gen. Tacomas (2016-2023)' started by 80sforlife, May 9, 2017.

Page 2 of 3

Page 2 of 3

Confused!!! Ground plane/ No Gound plane C.B. antenna

Confused!!! Ground plane/ No Gound plane C.B. antenna Help me identify this set up

Help me identify this set up Those 2016 Grills

Those 2016 Grills Taco christmas spirit

Taco christmas spirit Black Lug Nuts for Aftermarket Wheels

Black Lug Nuts for Aftermarket Wheels What to do with OEM Reverse Sensing holes?

What to do with OEM Reverse Sensing holes?