-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Quick Links: Suspension upgrade for loading up bed

Suspension upgrade for loading up bed  Advice please! What would you do differently first time purchasing a lift kit/suspension upgrade?

Advice please! What would you do differently first time purchasing a lift kit/suspension upgrade?  Headlight Assembly Recs

Headlight Assembly Recs  Differential Breather Mod for Dummies (Pics) Starting to get a vibration through the truck while accelerating

Differential Breather Mod for Dummies (Pics) Starting to get a vibration through the truck while accelerating  ABS light and wheel sensors help

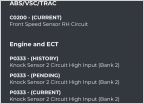

ABS light and wheel sensors help

P2440 the cheap way

Discussion in '2nd Gen. Tacomas (2005-2015)' started by Pyts, Nov 20, 2024.