-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

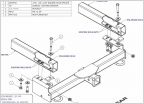

Plating the frame on my 2000 taco

Discussion in '1st Gen. Tacomas (1995-2004)' started by TurtleCrawler, Aug 6, 2020.

Forward facing car seat

Forward facing car seat STOP TRYING TO LOCATE THE DASH RATTLE! (No!!! Not another DASH RATTLE thread!)

STOP TRYING TO LOCATE THE DASH RATTLE! (No!!! Not another DASH RATTLE thread!) Front Receiver options?

Front Receiver options? Looking for Bilstein 4600 series shocks....

Looking for Bilstein 4600 series shocks.... Shocking shocks!

Shocking shocks! Stereo Upgrade

Stereo Upgrade