-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Remove - Replace - Install: 05+ CV Axles LCA’s / SPC UCA’s / ECGS Bushing / Toytec Coils

Discussion in '2nd Gen. Tacomas (2005-2015)' started by West450, Oct 30, 2017.

Tacoma Rock Lights to Dome

Tacoma Rock Lights to Dome 06 base 2.7 oil pan stripped drain plug

06 base 2.7 oil pan stripped drain plug Best cabin air filter for gen2

Best cabin air filter for gen2 2.7 base model recommendations for shocks.

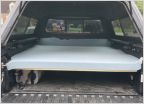

2.7 base model recommendations for shocks. For those of you who sleep in your truck, what is the best mattress?

For those of you who sleep in your truck, what is the best mattress? Low voltage cut out/alarm?

Low voltage cut out/alarm?