-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

[Solved] High Idle After Engine Replacement & Supercharger Install Diagnosis 3.4 5vz

Discussion in '1st Gen. Tacomas (1995-2004)' started by Dalandser, Jun 29, 2019.

I think these will work....but

I think these will work....but Full exhaust replacement

Full exhaust replacement Bad A/C Clutch, fix options?

Bad A/C Clutch, fix options? Battery Top Post

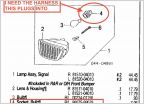

Battery Top Post Seeking part number for gen1 turn signal harness

Seeking part number for gen1 turn signal harness Remote Start Full kit?

Remote Start Full kit?