-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Quick Links: Can I make my 2017 passenger side floor board like a 2018 with the floor mat tabs?

Can I make my 2017 passenger side floor board like a 2018 with the floor mat tabs?  No leather portfolio for 2020 Tacoma

No leather portfolio for 2020 Tacoma  Correct 2020 rear speaker wire harness adapter?

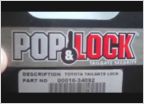

Correct 2020 rear speaker wire harness adapter?  Power tailgate lock; the definitive install!

Power tailgate lock; the definitive install!  Discovered an advantage to not having an auto-loking tailgate. Navigation system and topo maps

Discovered an advantage to not having an auto-loking tailgate. Navigation system and topo maps

UCA bolts came loose 2500 miles after installing a lift - what did I miss?

Discussion in '3rd Gen. Tacomas (2016-2023)' started by Reluctanse, Jun 1, 2022.

Page 2 of 2

Page 2 of 2