-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Front Hitch Receiver for Recovery?

Discussion in 'Recovery' started by SHADOWDRIFTER19, Aug 19, 2025.

Page 2 of 3

Page 2 of 3

12k lb Badlands Winch from Harbor Freight $299

12k lb Badlands Winch from Harbor Freight $299 Recommendations...

Recommendations... Check out my gear list

Check out my gear list Smittybilt X20 10K install

Smittybilt X20 10K install Snatch rope thickness and recovery points

Snatch rope thickness and recovery points Anyone wire their winch through a cab switch?

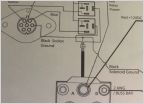

Anyone wire their winch through a cab switch?