-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

DIY Replacing Driveshaft Center Bearing

Discussion in '2nd Gen. Tacomas (2005-2015)' started by jmanscotch, Oct 18, 2017.

Page 12 of 12

Page 12 of 12

Any tricks for keeping truck cooler? AC wise.

Any tricks for keeping truck cooler? AC wise. Aftermarket TPMS

Aftermarket TPMS Wheel stud replacement

Wheel stud replacement Code 1408 L/R wheel speed sensor options???

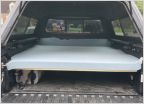

Code 1408 L/R wheel speed sensor options??? For those of you who sleep in your truck, what is the best mattress?

For those of you who sleep in your truck, what is the best mattress? Questions about TC Uniball UCAs...and uniballs in general

Questions about TC Uniball UCAs...and uniballs in general