-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Compression specs for all 1st and 2nd gen tacomas

Discussion in 'Technical Chat' started by 95 taco, Mar 19, 2014.

Oil filter cap wrench for WIX

Oil filter cap wrench for WIX Sound effect switch in cab? Wiring?

Sound effect switch in cab? Wiring? Inner steering bellows clamps

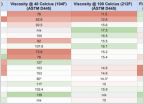

Inner steering bellows clamps Gear/Differential Oil Spec Comparison (nerdy data stuff)

Gear/Differential Oil Spec Comparison (nerdy data stuff) Too many wires going to my battery or not? What would you do?

Too many wires going to my battery or not? What would you do? Non intermittent wipers

Non intermittent wipers