-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Why is 2nd round of head bolt torquing spec-d in angles and not ft/lbs ?

Discussion in '2nd Gen. Tacomas (2005-2015)' started by foampile, Aug 7, 2015.

Page 2 of 2

Page 2 of 2

Need help with lift setup!

Need help with lift setup! Installing winch on my 2006 tacoma.

Installing winch on my 2006 tacoma. Best steel bumper suggestions

Best steel bumper suggestions Do I need new shocks and struts?

Do I need new shocks and struts? Anyone have trouble with Denso TPMS?

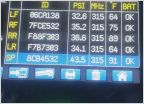

Anyone have trouble with Denso TPMS?